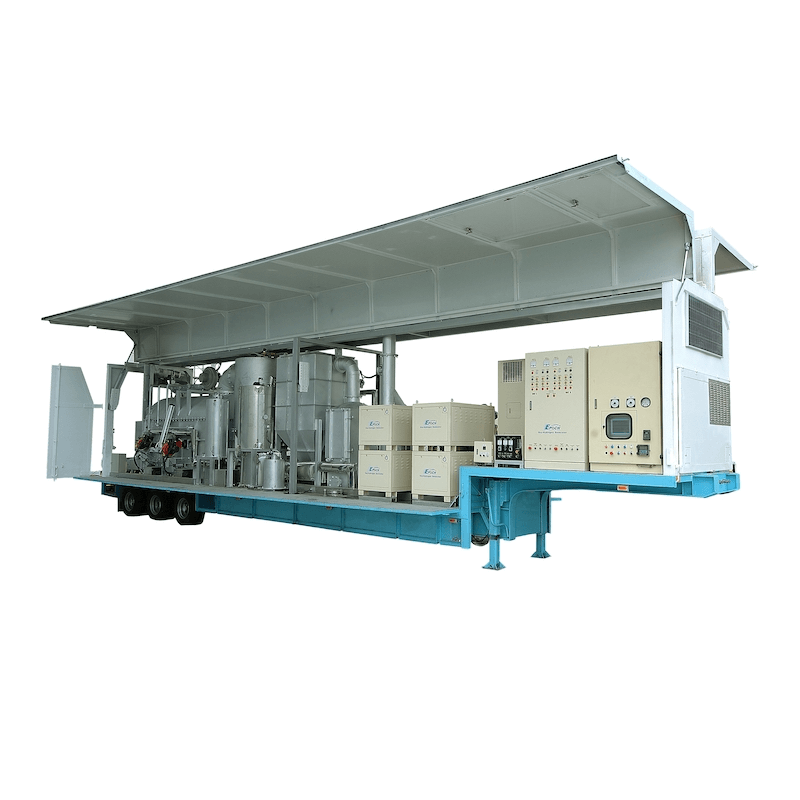

EP-2000 Mobile environmental protection and epidemic prevention vehicle

I. Functional Description: EP-2000 mobile environmental protection and anti-epidemic vehicle is the latest large-scale hydrogen-oxygen flame energy application product developed by the company. It utilizes the characteristics of high-temperature oxyhydrogen flame to carry out mobile epidemic prevention work with the highest efficiency, and can deal with infectious disease media locally. . Most of the previous general treatment methods transported the diseased media to the incineration plant for incineration, but the transportation process may lead to the deterioration of the epidemic. An important functional meaning of the mobile environmental protection and epidemic prevention vehicle is that it is a fire truck for infectious diseases. When the epidemic is serious, more than one department can be dispatched at the same time to prevent the spread of highly infectious diseases such as SARS and avian flu at the first time, and it can be used for the disposal of various wastes and garbage on weekdays.

Second, the product application areas: Ebola, SARS, avian flu and other anti-epidemic work, high-speed disease vector burning, hospital medical waste treatment, community, factory, camp, school and other cases of waste disposal.

III. Equipment Description: EP-2000 mobile environmental protection and anti-epidemic vehicle has a length of 40 feet and a weight of about 35 tons. The structure can be divided into "power equipment", "combustion equipment" and "air pollution equipment".

Power equipment

a. Diesel generator: 80~125KVA specification for the power demand of all systems operating in the epidemic prevention vehicle

b. Hydrogen-oxygen flame energy machine: EP-1200 electrolyzed water produces hydrogen and oxygen to provide waste combustion

2. Combustion equipment

a. Primary furnace: with 200,000 kcal oxyhydrogen diesel dual fuel burner, working temperature is about 600~800 °C, burning and cracking waste

b. Secondary furnace: with a 300,000-calorie hydrogen-oxygen diesel dual-fuel burner, the working temperature is about 800~1200°C, and the primary furnace is completely burned for the completely combusted material (the cracking temperature of Dioxin is 1050°C)

c. The maximum temperature resistance of all furnaces can reach 1600 °C

3. Air pollution equipment

a. Washing tower: spraying alkaline water mist with sodium hydroxide, performing "cooling (1100 → 150 ° C)", "acid gas generated after neutralization combustion", "filtering particles of combustion gas"

b. Bag dust collector: The inside is equipped with a long-tube bag to filter dust and particles of combustion gases.

c. Activated carbon: will filter out the odor of the dioxin and the combustion gases that are completely removed

|

Model Number |

EP-2000 |

||

|

Diesel generator ( kW / KVA / V ) |

120/380 |

||

|

Use voltage AC |

Control box + electrolytic cell (φ/ V/A ) |

(3/380/29)*2 |

|

|

R.O. Decanter (φ/ V/A ) |

(1/220/1)*2 |

||

|

Hydraulic and oxygen energy equipment working pressure (kg/cm²) |

1.5 |

||

|

Maximum water consumption (L/h) |

150 |

||

|

Maximum fuel consumption (L/h) |

50 |

||

|

In-furnace temperature |

Primary furnace (°C) |

600~800 |

|

|

Secondary furnace (°C) |

800~1200 |

||

|

Burner volume |

One furnace (m3) |

1.9 |

|

|

Secondary furnace (m3) |

3.6 |

||

|

weight (t) |

36 |

||